Odyssey hybrid version sound insulation and noise reduction case is an ingenious masterpiece worth referring to

Automobile sound insulation and noise reduction is a highly professional job, which requires the team to have extremely rich experience in disassembly and assembly. It is very important to disassemble and assemble automobile sound insulation and noise reduction, because no matter how professional the sound insulation construction is, if there is a slight improper operation during the disassembly and assembly process, it will cause various abnormal noises afterwards, and even cause the possibility of damage to accessories. Therefore, the choice of automobile sound insulation should be divided into three, six or nine grades. Sound insulation materials are relatively mature in the market at present, so there won’t be much worry, unless the price is ridiculously cheap. Finally, the construction team must have many years of experience in vehicle disassembly and assembly. Automobile sound insulation and noise reduction are all one-time construction, so it will be very troublesome to rework. Secondary disassembly and assembly does cause great loss to vehicle accessories. It is recommended that riders be cautious when choosing car sound insulation.

The following is a case of sound insulation and noise reduction construction of the Honda Odyssey gasoline-electric hybrid version, which is shared with riders in need for reference. The Odyssey model has abandoned the sound insulation performance due to the original design needs. Generally speaking, the sound insulation of the Odyssey is a major shortcoming of this car.

When the car owner does sound insulation, he also experiences minor changes and upgrades to the sound system. The car owner’s will is to focus on the sound insulation effect. The audio upgrade configuration is simple, and the effect is obviously improved. It mainly replaces the entire car speaker and installs a dsp four-channel power amplifier driver.

Renderings of all interior accessories disassembled.

A rendering of the completed sound insulation and shock-proof installation on the first floor of the chassis. The sound insulation and shock-proof brand adopts Japanese Flute God.

After the sound insulation and anti-shock installation is completed, a double layer of sound-absorbing cotton is laid.

Rear girder sound insulation

Interior sound insulation of fender

Sound insulation of girders on both sides

The hood is sound-insulated and shock-proof. The sound insulation in this place is mainly for the purpose of earthquake resistance. During high-speed driving, the vibration frequency of the hood is reduced, the sheet metal density of the hood is strengthened, and the downward transmission of noise is suppressed.

Interior sound insulation of fender

This is the sound-absorbing cotton added to the tire liner

Rear tailgate plastic interior shock-absorbing treatment,

Plus a layer of sound-absorbing cotton

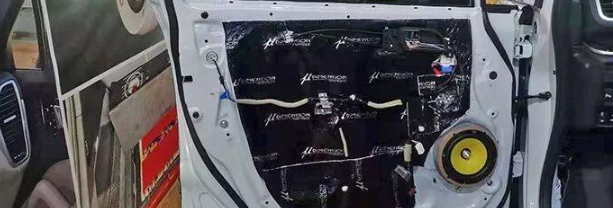

Sound insulation of middle door

Five door sealant strip installation

Front door German zero point horn installation completed

Front sound field tweeter installation

The middle door tweeter is installed in this location (discussed by the customer)

During interior trim reset installation

After the assembly was completed, it was tested with the customer. This sound insulation and noise reduction operation took 11 hours.